## Level Up Your Recycling Game: A Deep Dive into Plastic Optimization

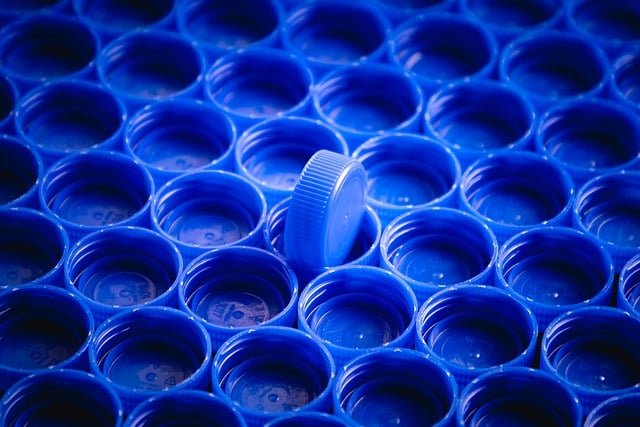

Let’s face it, we live in a world dominated by plastic. From our phones to our food packaging, it’s everywhere. While incredibly versatile, plastic’s durability also poses a significant environmental threat. The good news? We can all be part of the solution. This isn’t just about tossing that water bottle in the right bin – it’s about understanding the bigger picture of plastic recycling and how we can optimize the process for maximum impact.

### ## The What and Why of Plastic Recycling

Plastic recycling is more than just a feel-good practice – it’s a critical step towards a sustainable future. Essentially, it involves collecting, sorting, cleaning, and processing used plastic into new products. This reduces our reliance on virgin plastic production, which in turn conserves natural resources and minimizes pollution.

### ### The Environmental Imperative

The environmental benefits of plastic recycling are undeniable.

* **Reduced Landfill Space:** Landfills are overflowing, and plastic waste is a major culprit. Recycling helps divert plastic from landfills, freeing up valuable space and reducing harmful methane emissions.

* **Conservation of Resources:** Manufacturing virgin plastic requires significant amounts of fossil fuels and water. Recycling reduces the demand for these resources, lessening our environmental footprint.

* **Pollution Mitigation:** Plastic production and disposal contribute to air, water, and soil pollution. Recycling helps mitigate these impacts, safeguarding ecosystems and human health.

### ## Navigating the Recycling Maze: Understanding Different Plastic Types

Not all plastics are created equal. Different types of plastics have varying properties and recycling potential. Familiarizing yourself with these distinctions is crucial for effective recycling.

### ### The Resin Identification Code: Your Guide to Plastic Types

You’ve likely seen the numbers within the chasing arrows symbol on plastic products. This is the Resin Identification Code (RIC), and it provides valuable information about the plastic’s composition and recyclability.

1. **PET (Polyethylene Terephthalate):** Commonly used for beverage bottles, this plastic is highly recyclable and often turned into new bottles, fleece fabrics, or carpet fibers.

2. **HDPE (High-Density Polyethylene):** Found in milk jugs, shampoo