## Boosting Sustainability: Making Plastic Recycling More Effective

We get it. You’re bombarded with information about saving the planet, and sometimes it feels overwhelming. But here’s the thing: small changes, multiplied by millions of people, can make a real difference. One area where we can all step up our game? Plastic recycling.

It’s not just about tossing that empty water bottle in the blue bin – it’s about understanding the bigger picture and making conscious choices that support a circular economy for plastics. Let’s dive into how we can all contribute to increasing the recyclability of plastic products.

### ## Understanding the Challenges of Plastic Recycling

Before we jump into solutions, let’s address the elephant in the room: not all plastic is created equal.

Different plastics have varying chemical compositions, impacting their ability to be recycled. Some, like PET (think water bottles and food containers), are easily recyclable. Others, like polystyrene (often used in takeout containers and packing peanuts), are notoriously difficult to recycle and often end up in landfills.

### ### The Problem with Mixed Materials

Another major hurdle is mixed materials. Ever tried separating the plastic window from an envelope? It’s a pain, right?

Products made from multiple types of plastic or combined with other materials (like paper, metal, or adhesives) pose a significant challenge. These components need to be separated before recycling, which can be costly and complex.

### ### Contamination: A Recycling Roadblock

Imagine tossing a pizza box, greasy and covered in food remnants, into your recycling bin. Sounds gross, right? That’s contamination in action, and it’s a major problem for recycling facilities.

When non-recyclable materials or contaminated items end up in the recycling stream, they can damage equipment and reduce the quality of recycled materials.

### ## Designing for Recyclability: A Shared Responsibility

So, how do we tackle these challenges? It starts with designing products with recycling in mind. This requires a collaborative effort from manufacturers, designers, and consumers.

### ### Choosing the Right Plastic

The first step is opting for recyclable plastics whenever possible. PET and HDPE (commonly used for milk jugs and detergent bottles) are widely accepted for recycling and can be turned into new products multiple times.

### ### Simplifying Material Choices

Remember that envelope window? That’s a prime example of unnecessary material mixing. By minimizing the number of materials used in a product and opting for easily separable components, we can significantly improve recyclability.

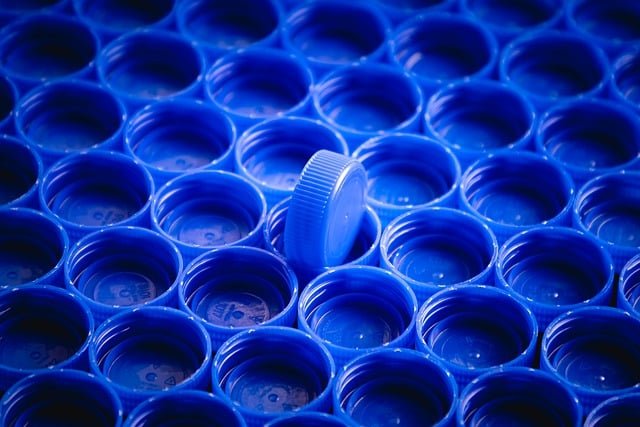

### ### Embracing Mono-Materials

Imagine a yogurt container made entirely from polypropylene (PP). That’s a mono-material product, and it’s a recycler’s dream! Using a single type of plastic throughout a product eliminates the need for complex separation processes, making recycling much more efficient.

### ## Empowering Consumers: Making Informed Choices

While manufacturers play a crucial role in designing for recyclability,