## The Future is Now: Exploring the Latest in Plastic Extrusion Tech

Plastic extrusion. It’s not exactly the first thing that pops into your head when you think “cutting-edge technology,” right? But hold on – this versatile process, responsible for everything from window frames to medical tubing, is undergoing a quiet revolution. Let’s dive into the exciting world of modern extrusion and see how these advancements are shaping the future.

### ## Smarter Machines, Smarter Manufacturing

Remember those clunky old machines from your high school shop class? Modern extrusion lines are a far cry from that. **Artificial intelligence (AI)** and **machine learning (ML)** are taking center stage, transforming extrusion into a precise, data-driven process.

Imagine this: an AI-powered system that constantly monitors every variable – temperature, pressure, material flow – and automatically adjusts parameters to maintain optimal production. **This isn’t science fiction; it’s happening right now.** The result? Reduced waste, higher quality products, and a manufacturing process that’s more efficient than ever before.

But it doesn’t stop there. **Predictive maintenance** is another game-changer. By analyzing data from sensors embedded within the machinery, these systems can anticipate potential problems *before* they even occur. This means less downtime, fewer headaches, and a significant boost to your bottom line.

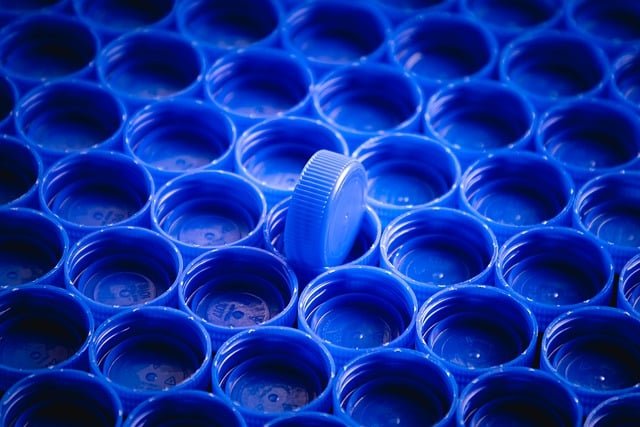

### ## Sustainability Takes Center Stage

Let’s face it, the plastics industry hasn’t always had the best environmental track record. But here’s the good news: **extrusion technology is evolving to embrace sustainability**.

One of the most exciting developments is the rise of **bioplastics**. These innovative materials, derived from renewable resources like cornstarch and sugarcane, offer a more eco-friendly alternative to traditional petroleum-based plastics. And guess what? Extrusion is playing a key role in bringing these sustainable solutions to market.

But it’s not just about the materials themselves. **Advanced extrusion techniques** are also minimizing environmental impact in the manufacturing process. Think **energy-efficient extruder designs**, **optimized cooling systems**, and **closed-loop recycling processes** that minimize waste and reduce reliance on virgin materials.

### ## Pushing the Boundaries of Design and Functionality

Remember when plastic