Maintaining plastic extrusion maintenance equipment ensures optimal performance and longevity. Regular upkeep reduces downtime and enhances product quality. Proper care minimizes costly repairs and extends the machine’s lifespan. Effective maintenance practices lead to consistent production and higher efficiency. Investing time in plastic extrusion maintenance proves beneficial for any manufacturing operation.

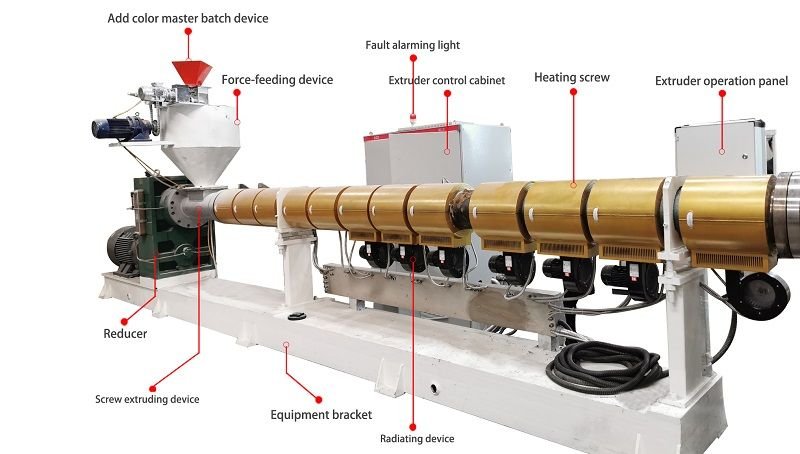

Understanding Your Plastic Extrusion Equipment

Key Components

Extruder Barrel

The extruder barrel houses the screw and directs the plastic material through the extrusion process. Regular inspection of the barrel ensures no obstructions or damage. A clean barrel prevents contamination and maintains product quality.

Screw

The screw moves and melts the plastic material inside the barrel. Inspect the screw for wear and tear to avoid inefficiencies. Replace worn screws promptly to maintain optimal performance.

Die

The die shapes the molten plastic into the desired form. Clean the die regularly to prevent buildup and ensure consistent product dimensions. Proper die maintenance enhances the overall quality of the extruded product.

Common Issues

Wear and Tear

Wear and tear occur naturally over time. Regularly inspect all components for signs of wear. Replace any worn parts to prevent further damage and maintain machine efficiency.

Overheating

Overheating can cause significant damage to the equipment. Monitor temperature settings closely. Ensure proper cooling systems are in place to prevent overheating.

Contamination

Contamination affects product quality and machine performance. Clean all components thoroughly to remove any contaminants. Regular cleaning routines help maintain high standards of production.

Daily Plastic Extrusion Maintenance Practices

Inspection

Visual Checks

Regular visual checks form an essential part of plastic extrusion maintenance. Inspect the extruder barrel, screw, and die for any visible signs of wear or damage. Look for discoloration, cracks, or other abnormalities. Early detection of issues prevents costly repairs and downtime. Consistent visual inspections ensure optimal equipment performance.

Checking for Unusual Noises

Unusual noises often indicate underlying problems. Listen for grinding, squeaking, or knocking sounds during operation. Address these noises immediately to prevent further damage. Regular auditory inspections enhance the effectiveness of plastic extrusion maintenance. Maintaining a quiet and smooth-running machine boosts productivity and product quality.

Cleaning

Cleaning the Barrel

Cleaning the barrel is crucial for effective plastic extrusion maintenance. Use a brass brush to remove resin residue inside and outside the barrel. Wipe off any residual melt to ensure a clean surface. A clean barrel prevents contamination and maintains high production standards. Regular barrel cleaning enhances the longevity of the equipment.

Cleaning the Screw

The screw requires thorough cleaning to maintain efficiency. Disassemble the screw and clean it with copper gauze to avoid scratching or rusting. Remove any buildup to ensure smooth operation. Proper screw cleaning is vital for plastic extrusion maintenance. Clean screws improve material flow and product consistency.

Weekly Plastic Extrusion Maintenance Tasks

Lubrication

Types of Lubricants

Proper lubrication is essential for plastic extrusion maintenance. Different lubricants serve various purposes. Synthetic oils provide excellent thermal stability. Mineral oils offer cost-effective solutions. Greases ensure long-lasting lubrication in high-pressure areas. Always choose lubricants that match the manufacturer’s recommendations. Correct lubricant selection enhances machine performance and longevity.

Lubrication Points

Identifying lubrication points ensures effective maintenance. Focus on the gearbox, bearings, and drive chains. Apply lubricants to these critical areas regularly. Proper lubrication reduces friction and wear. This practice minimizes downtime and extends equipment life. Consistent lubrication keeps the extrusion process smooth and efficient.

Calibration

Temperature Settings

Accurate temperature settings are crucial for plastic extrusion maintenance. Regularly calibrate the heating elements. Use precise instruments to measure temperature. Ensure the settings match the material requirements. Incorrect temperatures can cause defects in the extruded product. Proper calibration maintains product quality and consistency.

Pressure Settings

Pressure settings also require regular calibration. Monitor the pressure gauges closely. Adjust the settings according to the material specifications. Incorrect pressure can lead to poor product formation. Regular calibration ensures optimal extrusion performance. Maintaining correct pressure settings enhances overall production efficiency.

Monthly and Annual Plastic Extrusion Maintenance

Detailed Inspection

Wear and Tear Assessment

Monthly inspections should include a thorough assessment of wear and tear. Examine the screw, barrel, and die for any signs of degradation. Use precise measuring tools to check the dimensions of each component. Identifying wear early prevents major breakdowns. Regular assessments ensure the equipment operates at peak efficiency.

Component Replacement

Replace worn components promptly to maintain optimal performance. Order replacement parts from reputable suppliers. Follow the manufacturer’s guidelines for installation. Properly installed components extend the lifespan of the machine. Regular replacements reduce the risk of unexpected downtime.

Professional Servicing

When to Call a Professional

Call a professional service technician for complex issues. Schedule annual maintenance checks with certified experts. Professionals possess the skills to identify hidden problems. Regular professional servicing ensures compliance with industry standards. Expert intervention guarantees the longevity of the equipment.

What to Expect from a Service

Expect a comprehensive evaluation during professional servicing. Technicians will inspect all critical components. They will calibrate temperature and pressure settings. Lubrication points will receive attention. The service will include cleaning and replacing any worn parts. Professional servicing enhances the overall performance and reliability of the equipment.

Maintaining plastic extrusion equipment ensures optimal performance and longevity. Regular upkeep reduces downtime and enhances product quality. Proper care minimizes costly repairs and extends the machine’s lifespan. Effective maintenance practices lead to consistent production and higher efficiency. Investing time in plastic extrusion maintenance proves beneficial for any manufacturing operation.

Understanding Your Plastic Extrusion Equipment

Key Components

Extruder Barrel

The extruder barrel houses the screw and directs the plastic material through the extrusion process. Regular inspection of the barrel ensures no obstructions or damage. A clean barrel prevents contamination and maintains product quality.

Screw

The screw moves and melts the plastic material inside the barrel. Inspect the screw for wear and tear to avoid inefficiencies. Replace worn screws promptly to maintain optimal performance.

Die

The die shapes the molten plastic into the desired form. Clean the die regularly to prevent buildup and ensure consistent product dimensions. Proper die maintenance enhances the overall quality of the extruded product.

Common Issues

Wear and Tear

Wear and tear occur naturally over time. Regularly inspect all components for signs of wear. Replace any worn parts to prevent further damage and maintain machine efficiency.

Overheating

Overheating can cause significant damage to the equipment. Monitor temperature settings closely. Ensure proper cooling systems are in place to prevent overheating.

Contamination

Contamination affects product quality and machine performance. Clean all components thoroughly to remove any contaminants. Regular cleaning routines help maintain high standards of production.

Daily Plastic Extrusion Maintenance Practices

Inspection

Visual Checks

Regular visual checks form an essential part of plastic extrusion maintenance. Inspect the extruder barrel, screw, and die for any visible signs of wear or damage. Look for discoloration, cracks, or other abnormalities. Early detection of issues prevents costly repairs and downtime. Consistent visual inspections ensure optimal equipment performance.

Checking for Unusual Noises

Unusual noises often indicate underlying problems. Listen for grinding, squeaking, or knocking sounds during operation. Address these noises immediately to prevent further damage. Regular auditory inspections enhance the effectiveness of plastic extrusion maintenance. Maintaining a quiet and smooth-running machine boosts productivity and product quality.

Cleaning

Cleaning the Barrel

Cleaning the barrel is crucial for effective plastic extrusion maintenance. Use a brass brush to remove resin residue inside and outside the barrel. Wipe off any residual melt to ensure a clean surface. A clean barrel prevents contamination and maintains high production standards. Regular barrel cleaning enhances the longevity of the equipment.

Cleaning the Screw

The screw requires thorough cleaning to maintain efficiency. Disassemble the screw and clean it with copper gauze to avoid scratching or rusting. Remove any buildup to ensure smooth operation. Proper screw cleaning is vital for plastic extrusion maintenance. Clean screws improve material flow and product consistency.

Weekly Plastic Extrusion Maintenance Tasks

Lubrication

Types of Lubricants

Proper lubrication is essential for plastic extrusion maintenance. Different lubricants serve various purposes. Synthetic oils provide excellent thermal stability. Mineral oils offer cost-effective solutions. Greases ensure long-lasting lubrication in high-pressure areas. Always choose lubricants that match the manufacturer’s recommendations. Correct lubricant selection enhances machine performance and longevity.

Lubrication Points

Identifying lubrication points ensures effective maintenance. Focus on the gearbox, bearings, and drive chains. Apply lubricants to these critical areas regularly. Proper lubrication reduces friction and wear. This practice minimizes downtime and extends equipment life. Consistent lubrication keeps the extrusion process smooth and efficient.

Calibration

Temperature Settings

Accurate temperature settings are crucial for plastic extrusion maintenance. Regularly calibrate the heating elements. Use precise instruments to measure temperature. Ensure the settings match the material requirements. Incorrect temperatures can cause defects in the extruded product. Proper calibration maintains product quality and consistency.

Pressure Settings

Pressure settings also require regular calibration. Monitor the pressure gauges closely. Adjust the settings according to the material specifications. Incorrect pressure can lead to poor product formation. Regular calibration ensures optimal extrusion performance. Maintaining correct pressure settings enhances overall production efficiency.

Monthly and Annual Plastic Extrusion Maintenance

Detailed Inspection

Wear and Tear Assessment

Monthly inspections should include a thorough assessment of wear and tear. Examine the screw, barrel, and die for any signs of degradation. Use precise measuring tools to check the dimensions of each component. Identifying wear early prevents major breakdowns. Regular assessments ensure the equipment operates at peak efficiency.

Component Replacement

Replace worn components promptly to maintain optimal performance. Order replacement parts from reputable suppliers. Follow the manufacturer’s guidelines for installation. Properly installed components extend the lifespan of the machine. Regular replacements reduce the risk of unexpected downtime.

Professional Servicing

When to Call a Professional

Call a professional service technician for complex issues. Schedule annual maintenance checks with certified experts. Professionals possess the skills to identify hidden problems. Regular professional servicing ensures compliance with industry standards. Expert intervention guarantees the longevity of the equipment.

What to Expect from a Service

Expect a comprehensive evaluation during professional servicing. Technicians will inspect all critical components. They will calibrate temperature and pressure settings. Lubrication points will receive attention. The service will include cleaning and replacing any worn parts. Professional servicing enhances the overall performance and reliability of the equipment.