## The Future is Lighter: Unlocking Innovation with High-Performance Plastics

We live in a world obsessed with “more.” More speed, more efficiency, more innovation. But what if the key to achieving “more” actually lies in using “less”? This is where high-performance plastics come in. These aren’t your grandma’s Tupperware containers. These materials are revolutionizing industries from aerospace to healthcare, offering a potent combination of strength, lightness, and versatility.

### ## The Allure of Advanced Materials: Why Plastics?

For decades, metals have reigned supreme in manufacturing. However, the emergence of high-performance plastics is challenging this dominance. These materials, engineered to withstand extreme temperatures, resist chemicals, and bear significant loads, are proving their mettle across diverse applications.

### ### Lightweight Champions: Boosting Efficiency and Sustainability

One of the most significant advantages of high-performance plastics is their exceptional strength-to-weight ratio. Take, for instance, the automotive industry. By replacing heavier metal components with high-performance plastics, manufacturers can significantly reduce vehicle weight.

This weight reduction translates directly into improved fuel efficiency and reduced emissions, making a tangible impact on both the environment and the consumer’s wallet. Furthermore, the durability of these plastics ensures a longer lifespan for components, further minimizing waste and promoting sustainability.

### ### Design Freedom: Shaping the Future of Innovation

High-performance plastics aren’t just about practicality; they’re also about pushing the boundaries of design. Their inherent flexibility allows for complex shapes and intricate designs that would be difficult or impossible to achieve with traditional materials.

### ### From Concept to Reality: Streamlining Manufacturing

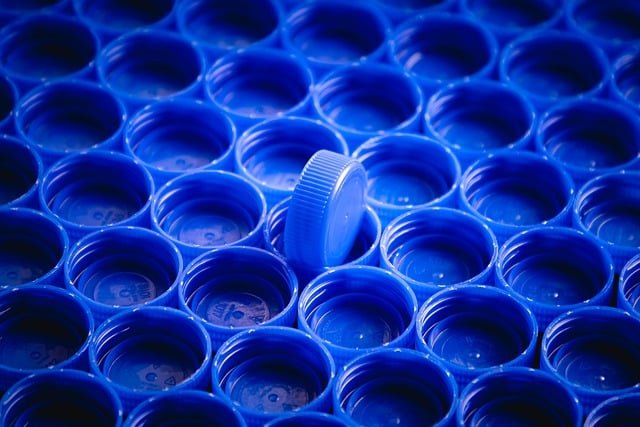

The benefits of high-performance plastics extend beyond the final product. Their unique properties lend themselves to efficient and cost-effective manufacturing processes. Injection molding, for example, allows for the rapid production of complex parts with high precision, reducing manufacturing time and costs.

This ease of manufacturing, coupled with the design freedom offered by these materials, empowers engineers and designers to bring innovative concepts to life quickly and efficiently.

### ## Beyond the Hype: Real-World Applications

The impact of high-performance plastics is already being felt across a multitude of industries. Let’s delve into some specific examples:

### ### Aerospace: Reaching New Heights